Ho rose ho robala ho beoa ho holang bakeng sa welding Poticioner

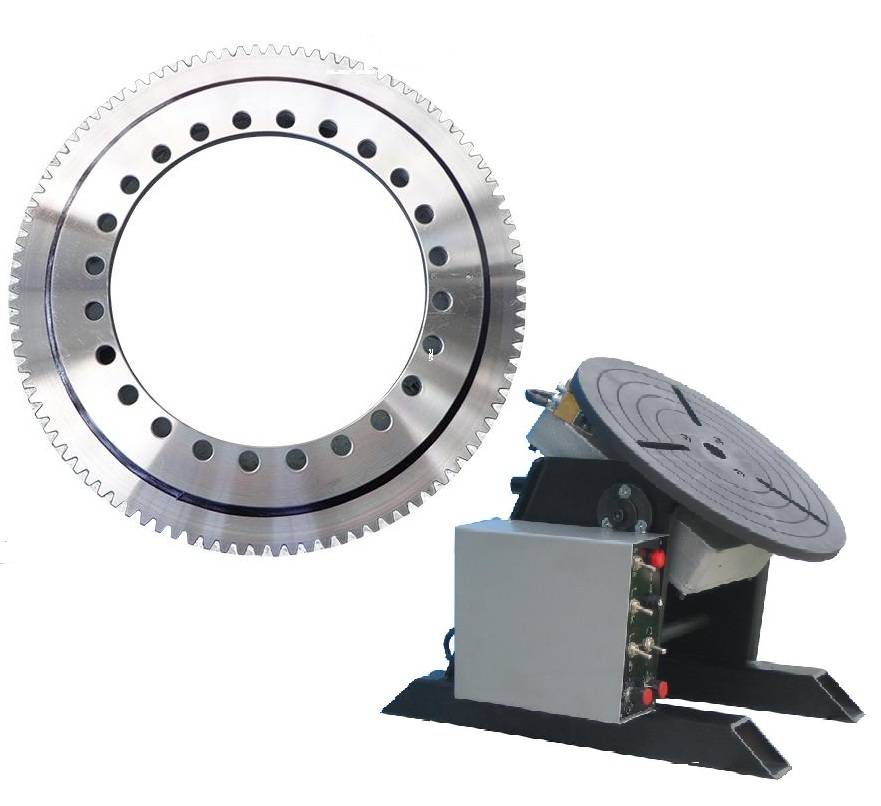

Lihlooho tsa Weldingli etselitsoe ho beha karolo boemong bo nepahetseng.Ka ke mofuta o thusang lisebelisoa tse thusang ho sebelisa bolotsanaho rokella ho llas.

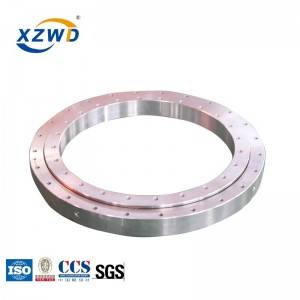

TheHo rekisa phetiso ea mechanisme bontšoa ho latela setšoantšo se latelang. Tsela ea eona ea ho phefumoloha ke ka mokhoa o motle: khanna koloiQoba ho Tšola-ho rokella ho lla-IDsbchch.

Ho hlophisoa ho hlophisitsoe hoho rokella ho lla, leho rokella ho lla e tsitsitse foranteng ea tšehetso. Lisebelisoa tse kholo ho serifi saho rokella ho llaMeshes lePinionHo sisinyeha ha moqomo o laoloang oa ho putlama, 'me mokhoa oa ho potoloha oa tafole o thehoa ke koloi ea enjene e hokahaneng le shaft ea ho fokola.

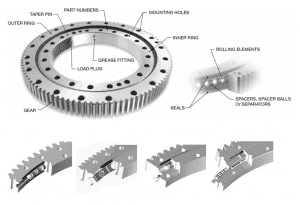

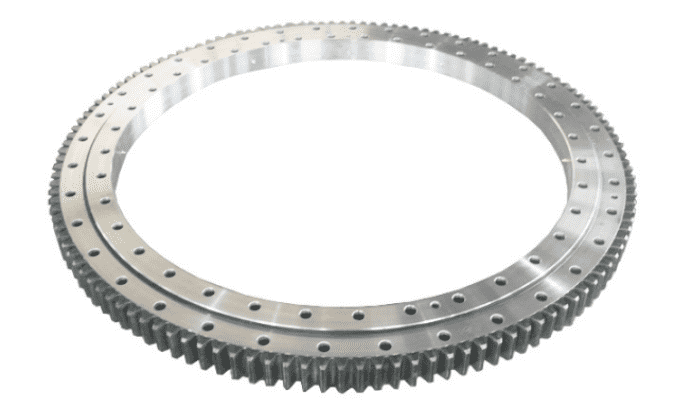

Ka sistiming ea ho sesa, ho hlophisoa ho hlophisitsoe hoho rokella ho lla, 'me ha ho khonehe ho hokahanngoa le sekhahla sa tšehetso kaho rokella ho lla. Sena ha se ntlafatse feela ho nepahala ho potoloha ha ho sebetsa, empa hape ho boetse ho ntlafatsa maemo a sebetsang. TheE le 'ngoe mola oa bone Tšoaea Ballho rokella ho lla e entsoe ka merabe e 'meli. E na le sebopeho le boima bo bobebe. Bolo ea tšepe e etsa hore poletso ea lintlha tse 'ne le pina ea arc.Xzwdho rokella ho llaHo latela kopo ea Wealding Poticioner, e khothalelitsoengho rokella ho llamofuta ke012. 60. 2000.

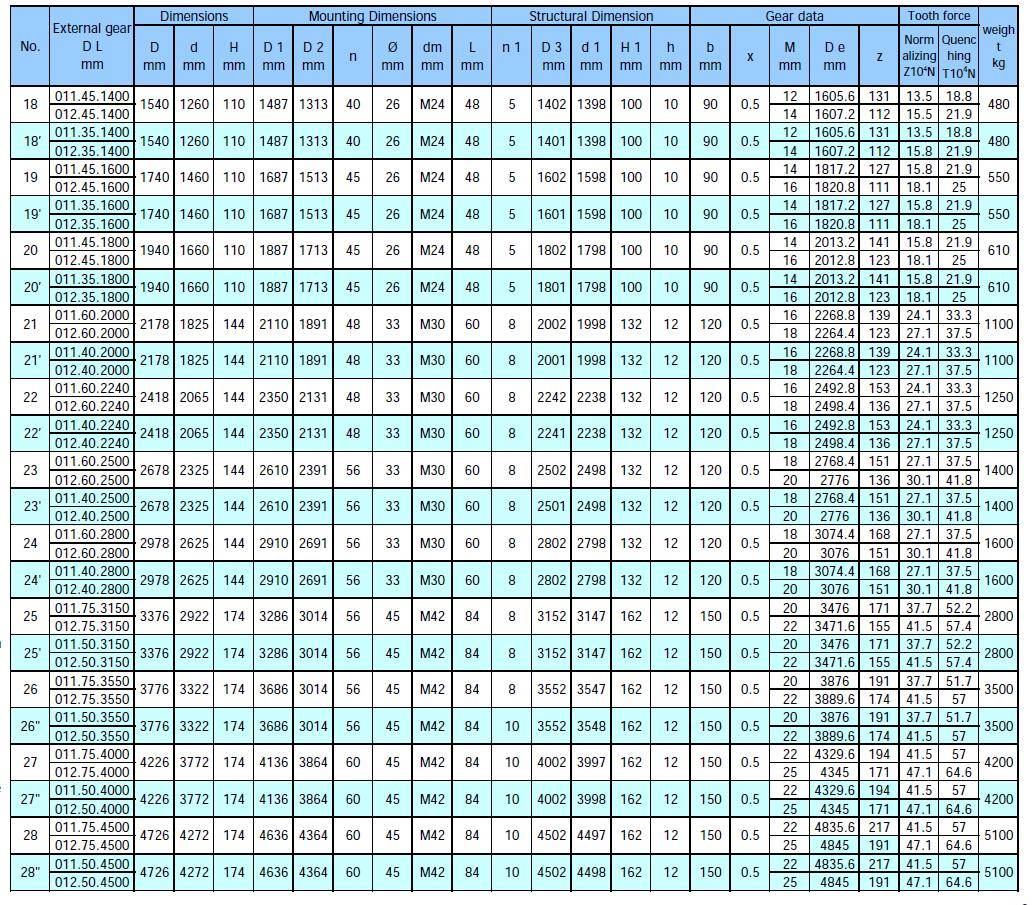

Tse latelang ke lethathamo la rona la ho robala, haeba u hloka mofuta leha e le ofe, o ka nthomella lengolo-tsoibila.

Le haeba o hlokaho rokella ho llaBakeng sa bahloekisi ba welding, ka kopo mpolelle kopo ea hau ka lengolo-tsoibila, re ka khothaletsa le ho ngola tse loketseng ho fetaho rokella ho llamolemong oa hau.

1. Melao ea rona ea tlhahiso e latela Standard Standers ea mochini JB / T2300-201, re fumane litsamaiso tsa boleng bo sa sebetseng (QMS) tsa ISO 9001: 2015 le GB / t19001-2008.

2. Re inehela ho R & D tsa ho bolaoa ka mokhoa o hlophisitsoeng ho na le tšusumetso e phahameng, sepheo se khethehileng le litlhoko tse ikhethang.

3. Ka lisebelisoa tse ngata tsa taw le katleho e phahameng ea tlhahiso, k'hamphani e ka etsa lihlahisoa tsa bareki kapele kamoo ho ka khonehang le ho khutsufatsa nako ea hore bareki ba letelle lihlahisoa.

4. Taolo ea rona ea boleng bo kahare e kenyelletsa tlhahlobo ea pele, tlhahlobo ea bobeli, e le ea boleng ba boleng ba ho netefatsa boleng ba sehlahisoa. Khamphani e na le lisebelisoa tse felletseng tsa liteko le mokhoa o tsoetseng pele.

5. Sehlopha se matla sa ho rekisa ka mor'a ho rekisa, rarolla mathata a bareki, ho fa bareki ba nang le lits'ebeletso tse fapaneng.