single row ball turntable slewing ring ring e nang le lisebelisoa tsa kantle

ree entsoe ka mehele ea litulo tse 2. E na le likarolo tse kopanetsoeng ka moralo, le boima bo bobebe. Libolo li kopana le lebelo la selikalikoe ka lintlha tse 'nè, tseo ka tsona matla a axial, matla a radial le motsotso oa sephetho a ka tsoaloang ka nako e le' ngoe.

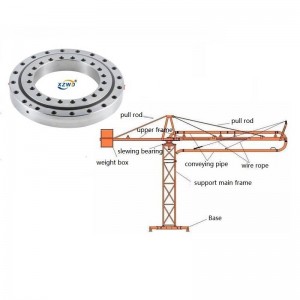

E ka sebelisoa bakeng sa conveyer, matsoho le li-positioners, leseli, li-crane tsa mosebetsi o mahareng, liepo le mechini e meng ea boenjiniere.

Sehlahisoa se fumanehang ho kenyeletsa: Single Row Ball, Three Row Roller, Cross Roller Tiisitsoeng le Tse sa Tiisoang tsa ka Hare tse Tsepamisitsoeng, Tlhaloso ea Kantle e Geared le e sa Rerang kapa e Lokisitsoeng esale Pele.

Re na le kemiso e tiileng ea tlhahiso ho netefatsa nako ea ho fana, kemiso ea tlhahiso e le ka tlase:

A. Forging reka nako: 15-20 matsatsi

B. Mokhoa oa tlhahiso:

1. Phetoho e thata: Matsatsi a 2-3

2. Kalafo ea mocheso oa Raceway: matsatsi a 2

3. Phetoho e ntle: matsatsi a 2

4. Ho khaola lisebelisoa: matsatsi a 4-5

5. Ho cheka: Matsatsi a 2-3

6. Phetoho ea ho qetela: Matsatsi a 2

7. Ho Kopanya le ho Hlahloba: Matsatsi a 2

C. Ho paka le ho isoa Port: matsatsi a 3-5

Ka ho feletseng ke matsatsi a 40-50

Lihlahisoa li sebelisoa haholo mecheng ea boenjiniere, mechini ea kaho, metjhini ea metallurgic le meepo,mochini o tsamaisang thepa, mochini o sireletsang tikoloho, mochini o bobebe oa indasteri, mochini oa lik'hemik'hale tsa petroleum,koloi ea boenjiniere, lisebelisoa tsa indasteri ea ntoa joalo-joalo.

Li-bearings tsa Turntable le Slewing Ring li sebelisa mela e le 'ngoe ho isa ho e meraro ea libolo kapa lirolara e le ho fana ka potoloho e thellang esita le tlas'a meroalo e meholo haholo.Ntle le meroalo ea radial le axial, li-bearings tsena li khona ho ts'ehetsa linako tse kholo maemong ao meroalo e ka tlosoang hole le sebaka sa ho jara.'s bohareng axis.

Li-Turntables le Slewing Rings li fanoa ka boholo ba metric le inch tse nang le bokhoni ba ho etsa li-interfaces tse ntseng li phahama hore li lumellane le kopo ea hau.Se khethollang Slewing Rings ho tloha Turntables ke ho kenyelletsa meno a gear ho mehele ea ka hare kapa ea ka ntle.

Re tsepamisa maikutlo le ho laola lintlha tsohle tsa tlhahiso, Feela bakeng sa ho fana ka lihlahisoa tse ntle ho bareki.

Thepa ea thepa ea ho bolaea hangata ke litšepe tse phahameng tsa alloy, joalo ka 42CrMo, 50Mn.

Thepa ea body rolling ke GCr15 mme e rekoa ho tsoa ho barekisi ba malapeng ka boleng bo holimo.

| No | Lisebelisoa tsa kantle | Boholo (mm) | Maemo a holimo (mm) | Bophahamo ba Sebopeho (mm) | Lintlha tsa lisebelisoa | Matla a likoloi10^4 KN | boima kg | ||||||||||||||||

| D | d | H | D1 | D2 | n | Φ | dm | L | n1 | D3 | d1 | H1 | h | b | x | M | De | z | N | T | |||

| 1 | 011.20.200 | 280 | 120 | 60 | 248 | 152 | 12 | 16 | M14 | 28 | 2 | 201 | 199 | 50 | 10 | 40 | 0 | 3 | 300 | 98 | 1.5 | 2.1 | 24 |

| 2 | 011.20.224 | 304 | 144 | 60 | 272 | 176 | 12 | 16 | M14 | 28 | 2 | 225 | 223 | 50 | 10 | 40 | 0 | 3 | 321 | 105 | 1.5 | 2.1 | 25 |

| 3 | 011.20.250 | 330 | 170 | 60 | 298 | 202 | 18 | 16 | M14 | 28 | 2 | 251 | 249 | 50 | 10 | 40 | 0 | 4 | 352 | 86 | 2.1 | 2.8 | 30 |

| 4 | 011.20.280 | 360 | 200 | 60 | 328 | 232 | 18 | 16 | M14 | 28 | 2 | 281 | 279 | 50 | 10 | 40 | 0 | 4 | 384 | 94 | 1.5 | 2.8 | 34 |

| 5 | 011.25.315 | 408 | 222 | 70 | 372 | 258 | 20 | 18 | M16 | 32 | 2 | 316 | 314 | 60 | 10 | 50 | 0 | 5 | 435 | 85 | 2.9 | 4.4 | 52 |

| 6 | 011.25.355 | 448 | 262 | 70 | 412 | 298 | 20 | 18 | M16 | 32 | 2 | 356 | 354 | 60 | 10 | 50 | 0 | 5 | 475 | 93 | 2.9 | 4.4 | 59 |

| 7 | 011.25.400 | 493 | 307 | 70 | 457 | 343 | 20 | 18 | M16 | 32 | 2 | 401 | 399 | 60 | 10 | 50 | 0 | 6 | 528 | 86 | 3.5 | 5.3 | 69 |

| 8 | 011.25.450 | 543 | 357 | 70 | 507 | 393 | 20 | 18 | M16 | 32 | 2 | 451 | 449 | 60 | 10 | 50 | 0 | 6 | 576 | 94 | 3.5 | 5.3 | 76 |

| 9 | 011.30.500 | 602 | 398 | 80 | 566 | 434 | 20 | 18 | M16 | 32 | 4 | 501 | 499 498 | 70 | 10 | 60 | 0.5 | 5 | 629 | 123 | 3.7 | 5.2 | 85 |

| 012.30.500 | 6 | 628.8 | 102 | 4.5 | 6.2 | ||||||||||||||||||

| 10 | 011.30.560 | 662 | 458 | 80 | 626 | 494 | 20 | 18 | M16 | 32 | 4 | 561 | 559 558 | 70 | 10 | 60 | 0.5 | 5 | 689 | 135 | 3.7 | 5.2 | 95 |

| 012.25/30.560 | 6 | 688.8 | 112 | 4.5 | 6.2 | ||||||||||||||||||

| 11 | 011.30.630 | 732 | 528 | 80 | 696 | 564 | 24 | 18 | M16 | 32 | 4 | 631 | 629 628 | 70 | 10 | 60 | 0.5 | 6 | 772.8 | 126 | 4.5 | 6.2 | 110 |

| 012.25/30.630 | 8 | 774.4 | 94 | 6 | 8.3/8.2 | ||||||||||||||||||

| 12 | 011.30.710 | 812 | 608 | 80 | 776 | 644 | 24 | 18 | M16 | 32 | 4 | 711 | 709 708 | 70 | 10 | 60 | 0.5 | 6 | 850.8 | 139 | 4.5 | 6.2 | 120 |

| 012.30.710 | 8 | 854.4 | 104 | 6 | 8.9/8.3 | ||||||||||||||||||

| 13 | 011.40.800 | 922 | 678 | 100 | 878 | 722 | 30 | 22 | M20 | 40 | 6 | 801 | 798 | 90 | 10 | 80 | 0.5 | 8 | 966.4 | 118 | 8 | 11.1 | 220 |

| 012.40.800 | 10 | 968 | 94 | 10 | 14.1/14 | ||||||||||||||||||

| 14 | 011.40.900 | 1022 | 778 | 100 | 978 | 822 | 30 | 22 | M20 | 40 | 6 | 901 | 898 | 90 | 10 | 80 | 0.5 | 8 | 1062.4 | 130 | 8 | 11.1 | 240 |

| 012.40.900 | 10 | 1068 | 104 | 10 | 14 | ||||||||||||||||||

| 15 | 011.40.1000 | 1122 | 878 | 100 | 1078 | 922 | 36 | 22 | M20 | 40 | 6 | 1001 | 998 | 90 | 10 | 80 | 0.5 | 10 | 1188 | 116 | 10 | 14 | 270 |

| 012.30/40.1000 | 12 | 1185.6 | 96 | 12 | 16.7 | ||||||||||||||||||

| 16 | 011.40.1120 | 1242 | 998 | 100 | 1198 | 1042 | 36 | 22 | M20 | 40 | 6 | 1121 | 1118 | 90 | 10 | 80 | 0.5 | 10 | 1298 | 127 | 10 | 14 | 300 |

| 012.30/40.1120 | 12 | 1305.6 | 106 | 12 | 16.7 | ||||||||||||||||||

| 17 | 011.45.1250 | 1390 | 1110 | 110 | 1337 | 1163 | 40 | 26 | M24 | 48 | 5 | 1252 | 1248 | 100 | 10 | 90 | 0.5 | 12 | 1449.6 | 118 | 13.5 | 18.8 | 420 |

| 012.35/45.1250 | 14 | 1453.2 | 101 | 15.8 | 21.9 | ||||||||||||||||||

| 18 | 011.45.1400 | 1540 | 1260 | 110 | 1487 | 1313 | 40 | 26 | M24 | 48 | 5 | 1402 | 1398 | 100 | 10 | 90 | 0.5 | 12 | 1605.6 | 131 | 13.5 | 18.8 | 480 |

| 012.35/45.1400 | 14 | 1607.2 | 112 | 15.5 | 21.9 | ||||||||||||||||||

| 19 | 011.45.1600 | 1740 | 1460 | 110 | 1687 | 1513 | 45 | 26 | M24 | 48 | 5 | 1602 | 1598 | 100 | 10 | 90 | 0.5 | 14 | 1817.2 | 127 | 15.8 | 21.9 | 550 |

| 012.35/45.1600 | 16 | 1820.8 | 111 | 18.1 | 25 | ||||||||||||||||||

| 20 | 011.45.1800 | 1940 | 1660 | 110 | 1887 | 1713 | 45 | 26 | M24 | 48 | 5 | 1801 1802 | 1798 | 100 | 10 | 90 | 0.5 | 14 | 2013.2 | 141 | 15.8 | 21.9 | 610 |

| 012.35/45.1800 | 16 | 2012.8 | 123 | 18.1 | 25 | ||||||||||||||||||

| 21 | 011.40/60.2000 | 2178 | 1825 | 144 | 2110 | 1891 | 48 | 33 | M30 | 60 | 8 | 2001 2002 | 1998 | 132 | 12 | 120 | 0.5 | 16 | 2268.8 | 139 | 24.1 | 33.3 | 1100 |

| 012.40/60.2000 | 18 | 2264.4 | 123 | 27.1 | 37.5 | ||||||||||||||||||

| 22 | 011.40/60.2240 | 2418 | 2065 | 144 | 2350 | 2131 | 48 | 33 | M30 | 60 | 8 | 2241 2242 | 2238 | 132 | 12 | 120 | 0.5 | 16 | 2492.8 | 153 | 24.1 | 33.3 | 1250 |

| 012.40/60.2240 | 18 | 2498.4 | 136 | 27.1 | 37.5 | ||||||||||||||||||

| 23 | 011.40/60.2500 | 2678 | 2325 | 144 | 2610 | 2391 | 56 | 33 | M30 | 60 | 8 | 2501 2502 | 2498 | 132 | 12 | 120 | 0.5 | 18 | 2768.4 | 151 | 27.1 | 37.5 | 1400 |

| 012.40/60.2500 | 20 | 2776 | 136 | 30.1 | 41.8 | ||||||||||||||||||

| 24 | 011.40/60.2800 | 2978 | 2625 | 144 | 2910 | 2691 | 56 | 33 | M30 | 60 | 8 | 2802 | 2798 | 132 | 12 | 120 | 0.5 | 18 | 3074.4 | 168 | 27.1 | 37.5 | 1600 |

| 012.40/60.2800 | 20 | 3076 | 151 | 30.1 | 41.8 | ||||||||||||||||||

| 25 | 011.50/75.3150 | 3376 | 2922 | 174 | 3286 | 3014 | 56 | 45 | M42 | 84 | 8 | 3152 | 3147 | 162 | 12 | 150 | 0.5 | 20 | 3476 | 171 | 37.7 | 52.2 | 2800 |

| 012.50/75.3150 | 22 | 3471.6 | 155 | 41.5 | 57.4 | ||||||||||||||||||

Hlokomela:

1. n1 ke nos ea likoti tsa ho tlotsa.Komiki ea oli M10×1JB/T7940.1~JB/T7940.2.Sebaka sa nnyo ea Oli se ka fetoloa ho latela kopo ea mosebelisi.

2. n-φcan e fetoha ho lesoba le tapiloeng, bophara ba lesoba le kentsoeng ke M, botebo ke 2M.

3. Matla a leino la tangential ka sebopeho ke matla a maholo a meno, matla a meno a tangential ke 1/2 ea max e le 'ngoe.

4. "K" ke coefficient ea phokotso ea tlatsetso.

XZWD Ho theosa le lilemo, re ne re fana ka sehlahisoa sa boleng bo holimo ho mosebelisi e mong le e mong mme ra fumana mokoloto o motle. Re na le sistimi e thata ea taolo ea boleng fekthering ea rona. e fetile ISO9001-2008 Quality System Certification le JG/T66-1999, JG/T67-1999, JG/T68-1999, JB/T2300-1999 ka litekanyetso tsa naha ea rona tsa boenjiniere le mechini.

1. Tekanyetso ea rona ea tlhahiso e ipapisitse le maemo a mochini a JB/T2300-2011, hape ho fumanoe Litsamaiso tsa Tsamaiso ea Boleng (QMS) tse sebetsang hantle tsa ISO 9001:2015 le GB/T19001-2008.

2. Re inehela ho R &D ea ho jara mokhoa oa ho bolaea ka mokhoa o nepahetseng haholo, morero o khethehileng le litlhoko.

3. Ka lisebelisoa tse ngata tse tala le katleho e phahameng ea tlhahiso, k'hamphani e ka fana ka lihlahisoa ho bareki kapele kamoo ho ka khonehang 'me e khutsufatsa nako ea hore bareki ba emele lihlahisoa.

4. Taolo ea rona ea boleng ba ka hare e kenyelletsa tlhahlobo ea pele, tlhahlobo ea bobeli, taolo ea boleng ba ts'ebetso le tlhahlobo ea sampole ho netefatsa boleng ba sehlahisoa.Khamphani e na le lisebelisoa tse felletseng tsa tlhahlobo le mokhoa o tsoetseng pele oa tlhahlobo.

5. Sehlopha sa tšebeletso se matla ka mor'a ho rekisa, ho rarolla mathata a bareki ka nako, ho fana ka litšebeletso tse sa tšoaneng tsa bareki.