XZWD ho fehla matla a letsatsi ka mela e le 'ngoe ea bolo ea maoto

Lesale la ho bolaela bolo le tlotsoa ka lihora tse ling le tse ling tse 100, selikalikoe sa ho roala se tlotsoa ka mor'a lihora tse ling le tse ling tse 50. Tlatsa tsela ea peiso ka mafura ho fihlela e tsoa ho litiiso.

E fane ka tlhokomelo ho lesale la ho hlaba le matha, u lokela ho le emisa ho hlahloba ha lerata, ts'usumetso kapa bothata bo bong bo sa khoneng ho matha .Trouble shooting le tiisetso ea hore ts'ebetso e ke ke ea e-ba le bothata leha e le bofe.

Mabapi le ho hloekisa, ha e khone ho hloekisa ka metsi ka ho toba, ho thibela metsi ho kena tseleng ea peiso, ho thibela ntho e thata kapa lithōle tseleng ea peiso le ho lebisa ho se lumellaneng ha meno a reng.

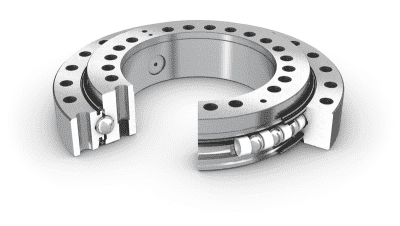

Kakaretso ea "slewing" e kenyelletsa masoba a ntseng a hola, masoba a lubricant le lisebelisoa tsa ho koala.

Liforomo tsa ho roala li kenyelletsa mela e le 'ngoe ea li-ball bearing tse nang le lintlha tse 'nè, mela e 'meli ea li-roller, mela e meraro ea cylindrical roller bearring.

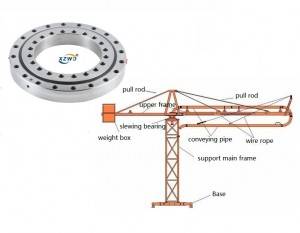

1. Mola o le mong oa li-ball bearings tse nang le lintlha tse 'nè o na le matla a phahameng a matla a matla, sesebelisoa se seholo sa mochine o hlokang matla a phahameng.Sch joaloka crane, excavator joalo-joalo.

2. Li-bearings tse peli tsa mela le mela e meraro ea rolara , ka lebaka la ho ntlafatsa bokhoni ba ho jara tlhokomelo ho tataiso ea bophahamo ba ho jara, mojaro o fapa-fapaneng ka ho latellana ka lihlopha tse fapaneng tsa lebelo le rolara, kahoo tlas'a boemo bo tšoanang ba ho roala, kahoo e etsa hore moeti a kopane haholoanyane. , ke mofuta o phahameng oa ho jara lesale la ho bolaea.

3. Mola o le mong o tšetseng rolara o na le boima bo phahameng ba Static, ts'ebeliso ea mantlha ea thepa ea ho khutsisa mosebetsing. Le bolo ea lintlha tse 'ne.ho belehakgahlano feela.

Lirolara tse tharo ka lebaka la boholo bo boholo ba axial le radial, ke ts'ebeliso ea mantlha ea mesebetsi e boima joalo ka mochini oa crune, ladle turret le metjhini e boima ea mehala.

Slewing lesale ka sebelisa liindasteri tse sa tšoaneng, empa maemong 'ohle e tla baka tšenyo ea lesale la ho bolaea,' me tšenyo e ile ea fumanoa ka bere ea ho bolaea, empa u se ke ua tseba hore na tšenyo e kae, e ka fumanoa feela tšenyo ea anatomy e feletseng.

Nakong ea ho qhaqhoa ha thepa ea ho bolaea, selikalikoe sa ka ntle sa ho bolaea se ne se kopanya karolo e ka holimo ea mochine, lesale la ka hare la ho beleha le ne le kopanya karolo e ka tlaase ea mochine.Ho hloekisa tiiso le ho phahamisa mochini ka thoko, ebe o ntša likurufu le liboutu.

Ntša bolo ea tšepe le boloko ba ho itšehla thajana le tlhahlobo holim'a bolo ea tšepe le ho itšehla thajana, haeba boloko ba ho itšehla thajana bo na le mapheo kapa tšenyo, ka kopo e khutlisetse ka nako. bolo ea tšepe.

1. Tekanyetso ea rona ea tlhahiso e ipapisitse le maemo a mochini a JB/T2300-2011, hape ho fumanoe Litsamaiso tsa Tsamaiso ea Boleng (QMS) tse sebetsang hantle tsa ISO 9001:2015 le GB/T19001-2008.

2. Re inehela ho R & D ea ho jara mokhoa o ikhethileng oa ho bolaea ka ho nepahala ho phahameng, morero o khethehileng le litlhoko.

3. Ka lisebelisoa tse ngata tse tala le katleho e phahameng ea tlhahiso, k'hamphani e ka fana ka lihlahisoa ho bareki kapele kamoo ho ka khonehang 'me e khutsufatsa nako ea hore bareki ba emele lihlahisoa.

4. Taolo ea rona ea boleng ba ka hare e kenyelletsa tlhahlobo ea pele, tlhahlobo ea bobeli, taolo ea boleng ba ts'ebetso le tlhahlobo ea sampole ho netefatsa boleng ba sehlahisoa.Khamphani e na le lisebelisoa tse felletseng tsa tlhahlobo le mokhoa o tsoetseng pele oa tlhahlobo.

5. Sehlopha sa tšebeletso se matla ka mor'a ho rekisa, ho rarolla mathata a bareki ka nako, ho fana ka litšebeletso tse sa tšoaneng tsa bareki.